Our company just completed an installation of 4-foot LED fluorescent-replacement tubes for a customer in Pasadena. These tubes use 11.6 watts as opposed to the 32 watts that the most efficient T8 fluorescent tube would use or the 34-40 watts that an inefficient T12 would use.

Our company just completed an installation of 4-foot LED fluorescent-replacement tubes for a customer in Pasadena. These tubes use 11.6 watts as opposed to the 32 watts that the most efficient T8 fluorescent tube would use or the 34-40 watts that an inefficient T12 would use.If LED lighting could save the customer money while providing the same or better light and reducing carbon emissions, it would be one of the best solutions available for going green. So let's use this installation as a case study to see if LEDs can deliver on their promise.

The Economics

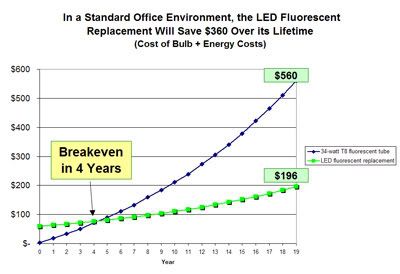

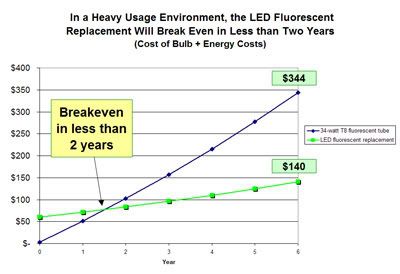

The retail price of one LED tube is $59.95. This is much higher than a $2 or $3 fluorescent tube, but if you do the math on the overall cost of the lighting you see that LEDs are an excellent investment.

The 56 LED tubes in this project cost $2,997 more than the cost of fluorescents (not including the fact that you'd have to buy 5 replacement fluorescents by the time one LED tube burns out). But because they use 20.4 fewer watts and are on 24/7, together they will save 10,007 kWh per year which translates to $1,438 in electricity costs EACH YEAR. So even if you exclude savings on maintenance and disposal fees associated with the mercury in fluorescents, the electricity savings will pay for the LED tubes in 2.1 years.

Add to this the fact that the City of Pasadena has a terrific energy efficiency rebate program and our customer will see a payback on this project in 0.6 years. This is an astonishing return on investment for any capital investment.

Another way to look at it is the net present benefit of the project, since the LEDs will save electricity for their entire 50,000 hour lifetime. Over the life of the tubes (approx. 6 years in a 24/7 usage environment) the net present value of the benefit without the rebate is $5,996.

Verdict: the economics are extremely sound.

The Light Quality/Quantity

One obstacle to the adoption of LED technology is customer concern about the amount of light and the light color. This installation allowed us to test these factors in a real-world environment.

Light Color

The before and after photos only tell part of the story. The camera, like the human eye, adjusts to the light color and amount of light. So the 'before' picture, to the right, looks like it's pretty white. But in the 'after' picture on the left below (really a 'during' picture since the installation was half completed at that point) you can see that the LEDs in the center and left aisles look white whereas the fluorescents on the right aisle look yellow/orange. We measured a color temperature of 4200K under the fluorescent fixtures and 6200K under the LED fixtures

. Pure daylight is generally in the 5400-5800K range, so the LEDs are putting out a high quality light.

. Pure daylight is generally in the 5400-5800K range, so the LEDs are putting out a high quality light.Light Quantity

We took before and after footcandle readings from three locations: directly under the fixture, 3 feet from the narrow edge of the fixture (to the side), and 5 feet from the broad edge of the fixture (near the wall). As expected, the LED lights were about 7% brighter directly under the light, just as bright off to the side, and 8% dimmer near the wall. So the amount of light is the same, but the distribution is more focused.

Verdict: the light quality/quantity is the same if not better.

The Environment

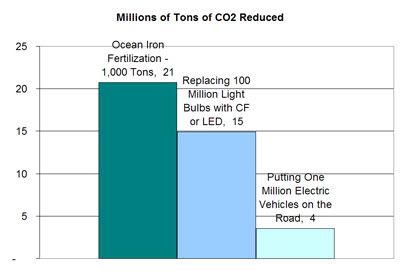

Why do I mention the environment last? Because while I think it's important, not all customers value it the most. And I believe that to make a meaningful impact on climate change or dependence on foreign oil we have to find solutions have a beneficial impact on the environment, but would make sense for the customer on an economic basis alone. To paraphrase Mary Poppins, saving money is the spoonful of sugar that makes the medicine of carbon reduction go down.

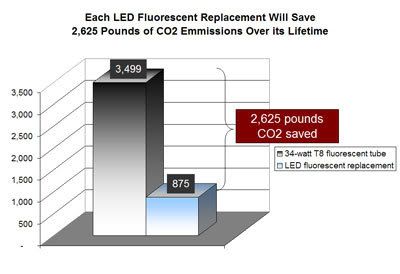

In this case, the environmental impact is hugely positive. First, LED tubes have no mercury. But perhaps more important are the carbon emissions prevented. As we mentioned above the lights in this project will use 10,007 fewer kWh per year. Using the US Green Building Council's estimate of 1.771 pounds of CO2 per kWh, this translates into a reduction of 17,723 pounds -- almost nine tons -- of CO2 per year.

Verdict: LED lighting is massively beneficial for the environment.

All in all, the project is a success on all fronts. And this is not science fiction. This is happening right now, today, in a parking garage in Pasadena. People are saving money, helping the environment, and reducing the strain on our electric grids all at the same time.